Stripping of metal parts

Paint stripping service for metal parts and hanging racks

Allows parts to be cleaned so they can be reused.

Stripping of metal parts

There are three metal part stripping machines that operate on silica sand.

Air is injected, forming a fluidized bed at a temperature of 450°C. The parts placed in a basket are cleaned in a one-hour cycle.

This process allows for the cleaning of hanging hooks from the painting process, as well as the recovery of metal parts contaminated with inorganic products, plastic, polyurethane, etc. Recommended only for carbon steel-based parts.

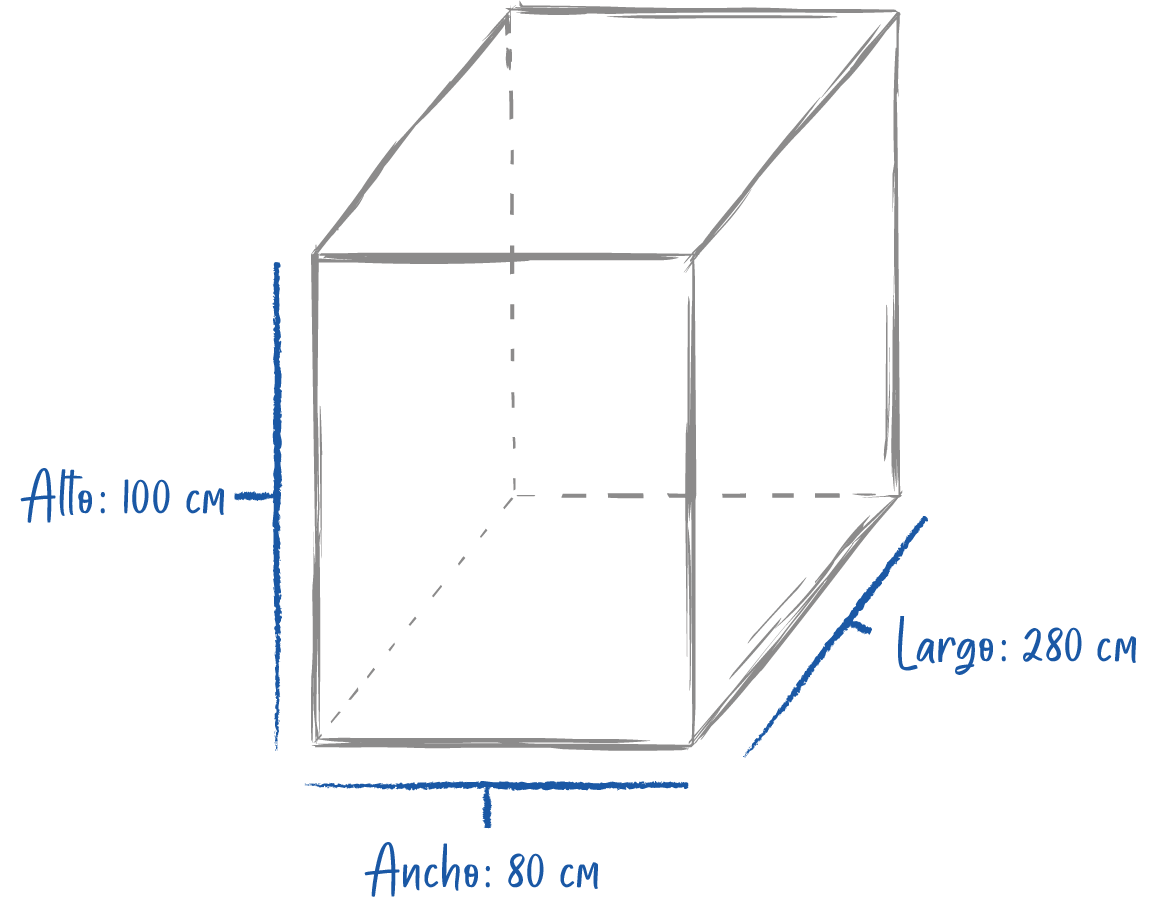

Its capacity is 3 cubic meters and the pieces can be: