ECOAT

We have two lines of Electrophoretic Painting (E-Coat) of the highest technology

Both lines are pretreated with zinc phosphate, providing up to 1,000 hours of salt chamber life for the processed parts.

ECOAT Electrophoretic paint

The Ecoat electrophoretic painting process, or electrophoretic coating, better known as Ecoat, involves immersing parts in a tub filled with demineralized water and paint. Once the parts are immersed, an electric current is applied, generating a chemical reaction in the paint that causes it to adhere to the surface. This creates a uniform layer on the part, as the parts are insulated when painted, preventing the paint from becoming thicker.

The pretreatment for this line is based on zinc phosphate and consists of 11 stages, the first being an immersion degreaser and the second a spray degreaser. This ensures that the oils used in the manufacture of the parts are completely removed. The remaining stages are immersion.

The painting process involves a paint vat and three subsequent rinses, which also combine the first by immersion, the second by spraying, and the third by immersion. This process guarantees a uniform, defect-free finish on the parts.

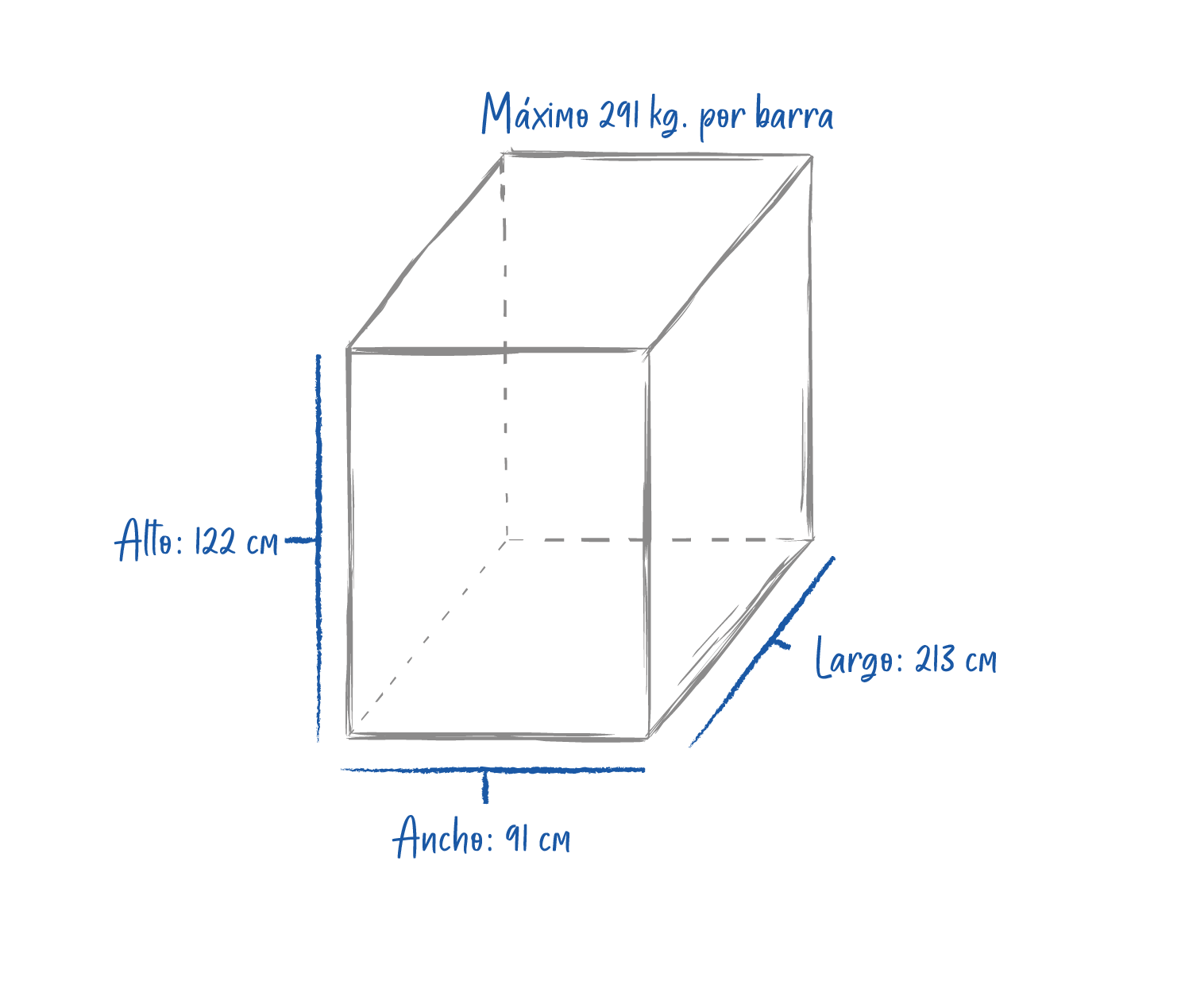

The current process has bars that are carried through each stage of the process.

The process has the capacity to produce 20 bars per hour and the cycle time is 2 hours.